- Piezo injector testing borders how to#

- Piezo injector testing borders manuals#

- Piezo injector testing borders manual#

Regardless, on our services the ring is replaced.īelow is the listing from the tool catalog on the injector removal tool. You should be able to tell if the Teflon ring has been leaking, there will be signs of combustion on the ring.

Piezo injector testing borders manual#

What this part of the service manual is missing is the special tool, I have listed it below.

Piezo injector testing borders how to#

Here you will see the instructions on how to remove the air or direct injectors. V-6 models have 2 fuel rails, while the smaller 3-cylinder models only have 1 fuel rail. The fuel rails can now be separated from the direct injectors, and cylinder heads.

I believe they require a 15mm socket for removal. Once the fuel injectors are removed you can remove the 2 lock nuts from each fuel rail. Removal of the fuel injectors (usually red in color), avoid using vice grips or screwdrivers to pry on these, the plastic connectors may be damaged.

Piezo injector testing borders manuals#

I have attached some snippets from the service manual (this particular manual was for a ~2008 225 Optimax, manuals may vary) I recently got asked by a forum member here, on how to properly remove fuel injectors and direct injectors from an Optimax motor. Last edited by InjectorService 12-07-2019 at 08:57 PM. Questions, anything, let me know in this thread! Let me know what you think, good, bad, UGLY, I want to hear feedback from you guys. I have provided a link to my website below, as well as my Instagram profile, I post when I can but sometimes work gets in the way. I'm sure I missed something along the way.

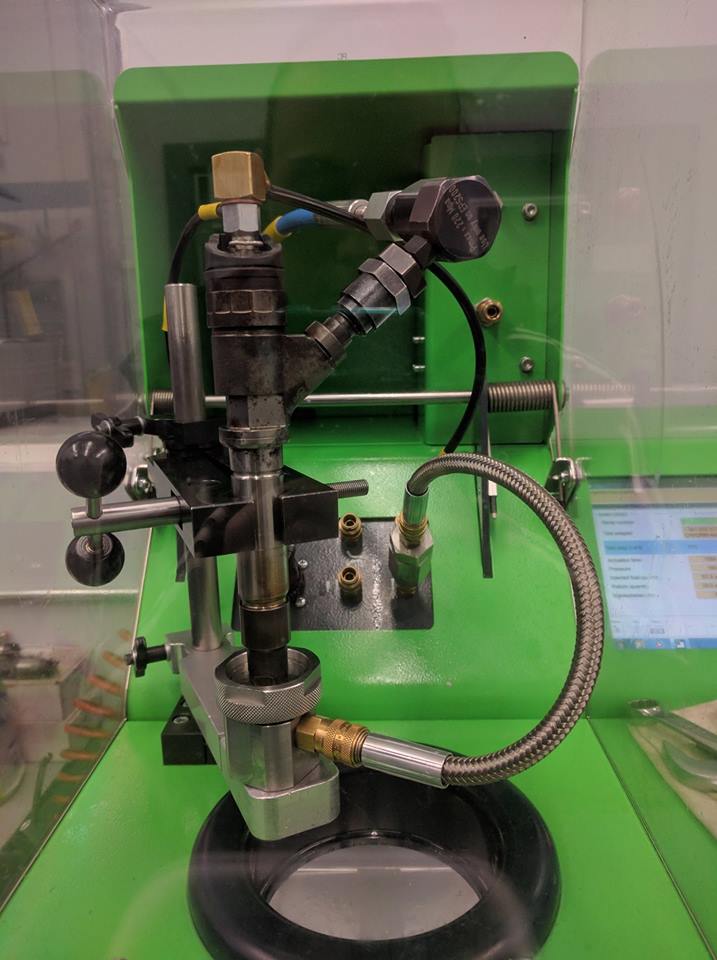

The final step is re-testing, where we repeat all the initial tests and compare the results. This test is repeated until we are satisfied that there are no more deposits in the injectors. This not only opens and closes the pintle allowing cleaning fluid into the injector, but it actually back-flushes any deposits or debris from the injector itself. While the injectors sit in the cozy bath, they are cycled using our testing machine. Next we take the injectors and put them in a heated ultrasonic bath, with a cleaning solution formulated specifically for this task. The tiny internal filters are removed, along with all o-rings, seals, and rubber spacers. That being said we find that these tests are a good indication of most issues and anything more specific in terms of RPM or Duty Cycle usually does not show anything we can't see on our regular tests.Īfter this is done, the injectors are disassembled for cleaning. If there are any other tests that you require, we can custom tailor our service to meet your needs. We take your fuel injectors that have been removed from your motor, we test them for flow pattern consistency, sticking shut or leaking, static flow rates (injector held wide open), dynamic flow rate (simulates regular use conditions, from cranking to 5000rpm), inductance (measures the actual ele ctrical magnetic field strength created by the internal coil). What do we do? - SIMPLE, We test, clean and service fuel injectors! Lets keep this one for injector related posts.ĮNOUGH ABOUT ME, LETS GET TO THE GOOD STUFF! Anyways if you want to say hi click the link below to my introduction thread. I'm pretty new here, but have been reading on SnF for quite a while. We clean, test, and service fuel injectors in almost anything, but we specialize in marine applications.

Hey guys! I'm Blake and I own and operate Canadian Fuel Injection Service.

0 kommentar(er)

0 kommentar(er)