They compress axially when loaded and can be found in suspension systems for vehicles or machinery where they support the weight. Helical compression springs are the most common type of coil spring used in mechanical systems. Some common examples include helical compression springs, helical extension springs, torsion springs, tapered springs, and conical springs. There are many different types of coil springs available on the market today. This stored energy can be harnessed for various purposes, such as supporting the weight of a vehicle or absorbing shock. The amount of energy stored depends on the spring’s dimensions, wire diameter, and number of coils. Definition of Coil Springs and Their FunctionĪ coil spring is essentially a mechanical spring that stores energy when compressed or extended, returning to its original shape when the force applied to it is released. The primary function of coil springs is to resist deformation or compression when force is applied. They are made from metal wire, wound into a helix shape.Ĭoil springs come in various sizes and shapes and are used in a wide range of applications, from suspension systems in cars to door hinges. So let’s dive in! Understanding Coil SpringsĬoil springs are mechanical devices designed to absorb shock and store energy. In this article, we will explore the factors that can cause coil springs to weaken over time and ways to maintain them for optimal performance. The short answer is yes, but there’s more to it than that.

One question often arises when talking about coil springs is whether they weaken over time. They are vital in absorbing shock, supporting, and maintaining stability during operation. These versatile springs can be found in everything from cars and trucks to tractors and heavy-duty machinery. The importance of coil springs in mechanical systems cannot be overstated.

The Importance of Coil Springs in Mechanical Systems When force is applied to the spring, the coils compress or expand, absorbing the force and releasing it once it has been removed. They are typically made from metal wire coiled into a helical shape. What are Coil Springs?Ĭoil springs are a type of mechanical spring that is designed to absorb energy when it is compressed or extended. Without coil springs, many machines wouldn’t function properly. These springs are designed to absorb shock and support various applications, from cars and trucks to heavy-duty industrial equipment. Quality first, QA/QC is one of the most important departments in our company.Coil springs are an integral part of modern machinery and mechanical systems. A complete set of CNC Spring coiling machine & wire bending machine to processing the wire diameter from 0.15mm to 8.0mm, especially including the new technology of the Camless machine with wire rotation function and the applying of the Camera Spring Length Gauge on the Compression Spring Machineģ.

#Spring compression tester professional#

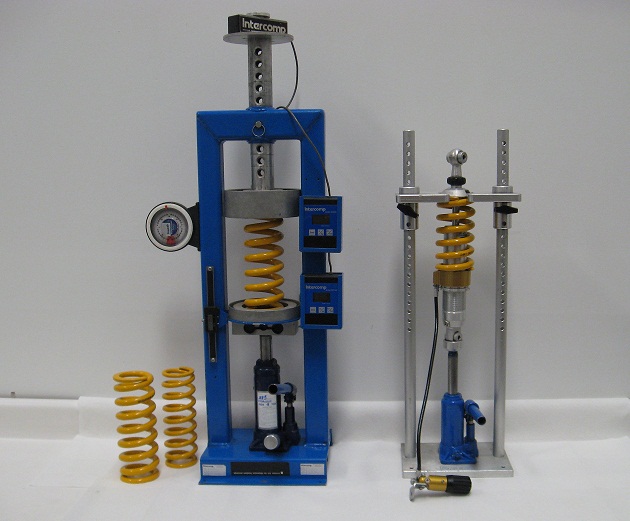

A complete production line from Design, Own Processing centre for spareparts & worktable, Importing Japan Sanyo and Yaskawa motors, Importing TaiWan Brand controlling system, Finishing operation, Inspection centre, Testing team and Professional vacuum packing with Fumigated wooden case.Ģ. The spring testing machine is mainly used to measure and analyze the mechanical performance ( tensile force, compressive force, displacement, and stiffness etc) of the springs ( cylinder spring, butterfly spring, tower-shaped spring, closing ring, flat spring, deformed spring and other precision spring).ġ. XD-AZ-50 spring testing machine with accurate printed recording for tensile forceġ, testing load by setting length 2, testing load by setting deformation

0 kommentar(er)

0 kommentar(er)